Understanding Code 28.99.39: A Guide to Industrial Agitator Vessel Manufacturing

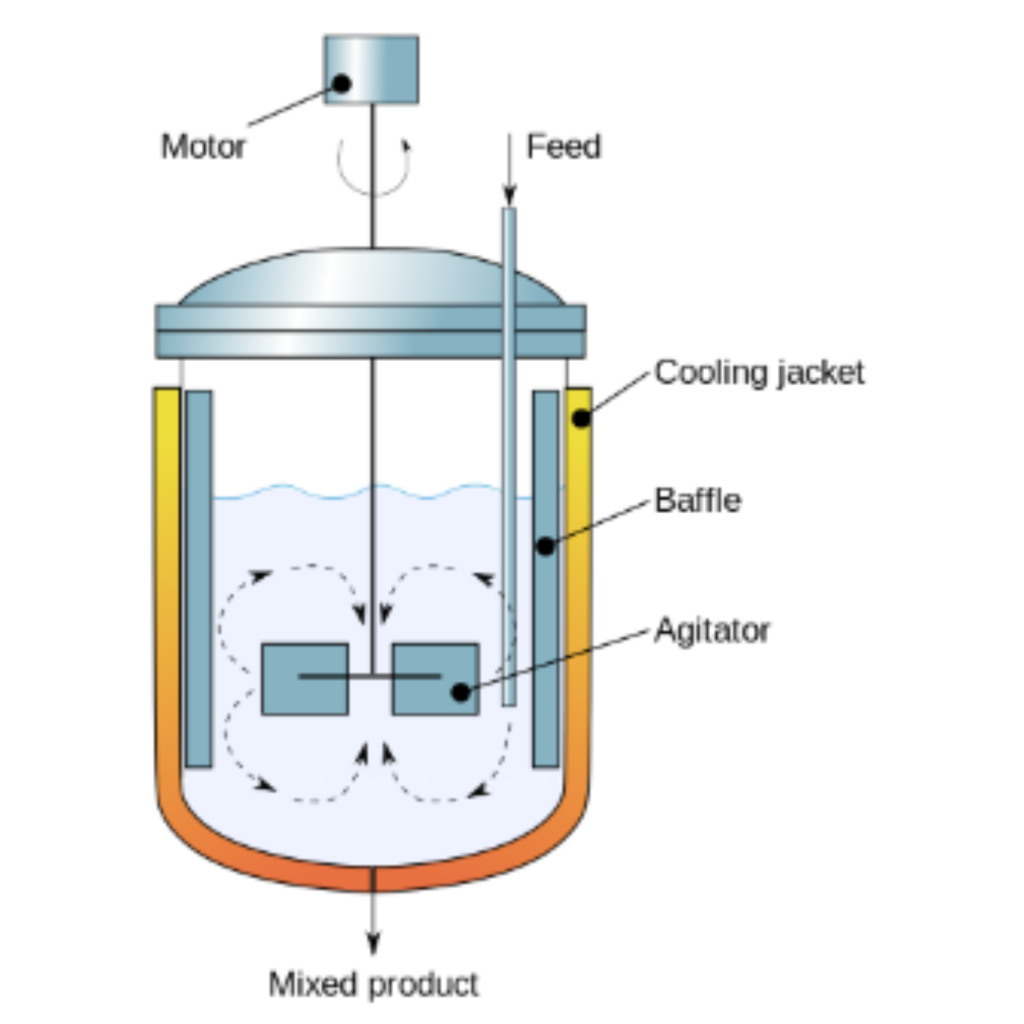

Code 28.99.39 refers to the classification within the Customs Tariff Statistics Position, primarily identifying agitator vessels—also known as mixing tanks or stirred reactors. These vessels are integral in various industries including chemical, pharmaceutical, food processing, cosmetics, and petrochemical sectors. They serve as critical components where precise blending, emulsification, suspension, and heat exchange processes are conducted under strict control.

Our in-depth focus is on the production capacity of these vessels, detailing factors that affect output, design considerations, material choices, and technological advancements in the 28.99.39 agitator vessel category.

Production Capacity of Agitator Vessels: Key Metrics and Performance Standards

The production capacity of an agitator vessel is defined by its volume, motor power, agitator type, operation time, and material compatibility. Standard capacities range from 50 liters to over 100,000 liters, depending on the intended application.

Primary Determinants of Production Capacity:

Tank Volume (L or m³): The total internal capacity directly affects the batch size. Industries with mass production needs typically require high-capacity units, often over 10,000 liters.

Agitation Speed (RPM): Higher RPMs enable faster homogenization but require stronger materials and enhanced motor durability.

Mixing Efficiency: Advanced blade geometry and turbine or anchor agitator types drastically influence the effective throughput per cycle.

Operational Continuity: Continuous vs. batch operation alters overall yield. Continuous vessels maintain higher production rates over time.

In real-world production lines, 28.99.39 classified vessels often integrate into SCADA-controlled systems, ensuring automated control of pressure, temperature, and mixing cycles.

Materials and Construction: Enhancing Durability and Efficiency

The construction materials of agitator vessels significantly influence both the lifespan and the production output. Stainless steel—particularly AISI 304 and 316L grades—is the most common due to its resistance to corrosion, chemical wear, and microbial contamination.

Advanced Material Options:

Duplex Stainless Steel: Offers increased strength and corrosion resistance in highly reactive environments.

Hastelloy and Titanium: Used for specialized pharmaceutical or nuclear applications.

Glass-Lined Steel: Essential for aggressive chemical reactions requiring non-stick, corrosion-resistant interiors.

Weld seams, surface finishes (e.g., mirror polishing), and sanitary design elements (like CIP/SIP ports) play key roles in maintaining sterile conditions, particularly in food and biopharma sectors.

Design Optimization: From Impeller to Geometry

Production capacity isn’t just about tank size; it’s about the efficiency of every design element.

Impeller Design:

Different impellers cater to different mixing objectives:

Axial Flow Impellers (e.g., Marine Propellers): Suitable for rapid bulk mixing.

Radial Flow Impellers (e.g., Rushton Turbines): Better for gas-liquid dispersion and reaction vessels.

Helical and Anchor Agitators: Optimal for viscous materials like creams, syrups, or polymers.

Baffle Integration:

To prevent vortex formation and improve mixing homogeneity, baffles are installed. Their number, angle, and spacing affect energy efficiency and batch uniformity.

Geometry and Aspect Ratio:

Vessels are designed with specific height-to-diameter ratios (typically between 1:1 to 3:1) to optimize fluid dynamics. Improper proportions lead to dead zones or over-shearing.

Automation and Control Systems in Production

Modern agitator vessel manufacturing under code 28.99.39 often includes PLC and HMI-based systems to monitor and adjust parameters such as:

Agitation speed

Torque

Temperature

Pressure

Flow rates

Real-time sensors and feedback loops allow for automated recipe management, error detection, and performance logging—resulting in minimal downtime and maximized output.

Industry-Specific Production Use Cases

Pharmaceutical Sector:

Agitator vessels here must comply with GMP, FDA, and EU Annex 1 regulations. Batch documentation, particle-free mixing, and sterile validation protocols are mandatory. Production batches usually range from 100 L to 10,000 L.

Food & Beverage Sector:

Agitator tanks are used in dairy, beverage, and flavor mixing operations. They include features like pasteurization jackets, scraper blades, and vortex-free blending mechanisms. Capacities extend up to 50,000 L in continuous beverage lines.

Chemical Manufacturing:

From polymers to solvents, chemical industries rely on corrosion-resistant, pressurized mixing systems. These vessels must endure high-temperature exothermic reactions and acidic mixtures, requiring extreme build quality.

Global Standards and Compliance for 28.99.39 Equipment

To ensure safety and operational compliance, production capacity and vessel construction under 28.99.39 must align with international codes:

ASME Section VIII Division 1 & 2 (Pressure Vessels)

EN 13445 (Unfired Pressure Vessels)

ATEX Directive for Explosive Atmospheres

ISO 9001 and ISO 14001 Standards

These ensure that every vessel, regardless of production capacity, meets the rigorous demands of international process safety.

Production Scalability: From Prototyping to Mass Manufacturing

Manufacturers of 28.99.39 agitator vessels must offer scalable solutions:

Prototype Units (5–100 L): Used in R&D labs and pilot trials.

Mid-Capacity Units (500–5,000 L): For specialty batch production.

High-Capacity Systems (10,000+ L): Fully integrated into industrial process lines.

Customizable options include multi-jacketed tanks, modular skids, vacuum-rated vessels, and mobile mixing stations, enabling manufacturers to meet varying demands across global markets.

Energy Efficiency and Sustainability in Modern Mixing Systems

As environmental concerns grow, manufacturers now prioritize energy efficiency and minimal environmental footprint. This includes:

High-efficiency motors with inverter control systems.

Optimized agitator blade geometry to reduce torque and energy use.

Renewable energy integration into plant operations.

Eco-friendly cleaning systems that reduce water and chemical consumption.

These innovations not only reduce operational costs but align with ESG (Environmental, Social, and Governance) compliance strategies.

Conclusion: Investing in Production-Optimized Agitator Vessels

The 28.99.39 agitator vessel production capacity directly influences operational scalability, batch consistency, and product integrity across numerous industries. As production demands rise, investing in efficient, compliant, and smart mixing systems becomes non-negotiable. From raw material blending to final product homogenization, these vessels are the heart of the process.

High-capacity, high-precision agitator vessels ensure that every drop counts, every batch performs, and every operation meets both regulatory and commercial expectations.